Safety measures we take

At SW Maintenance Services, we understand that safety is paramount in every aspect of industrial maintenance and engineering. As a company that installs and maintains machinery across various industries, including food production and fabrication, we recognise the critical importance of stringent safety measures. Here’s an in-depth look at the robust safety protocols and practices that underpin our operations.

A Culture of Safety

Safety isn’t just a policy at SW Maintenance Services; it’s ingrained in our culture. From the moment a project begins to its completion, we prioritise the well-being of our employees, clients, and the surrounding environment. This commitment to safety ensures that we not only meet but often exceed industry standards.

Comprehensive Training Programmes

Our engineers and technicians undergo rigorous training to ensure they are well-versed in the latest safety protocols and procedures. This training covers:

- Equipment Handling: Proper use and handling of all machinery and tools to prevent accidents and injuries.

- Emergency Procedures: Detailed protocols for responding to emergencies, including equipment failures and workplace accidents.

- Health and Safety Regulations: Continuous education on the latest health and safety regulations to ensure compliance with all legal requirements.

Preventative Measures

Preventative maintenance is a cornerstone of our operations, and it plays a critical role in our safety strategy. By identifying potential issues before they become serious problems, we can prevent accidents and ensure the safe operation of machinery. Our preventative measures include:

- Regular Inspections: Routine inspections of all equipment to detect wear and tear or potential hazards.

- Scheduled Maintenance: Timely maintenance of machinery to keep it in optimal working condition and prevent unexpected failures.

- Risk Assessments: Comprehensive risk assessments for each project to identify and mitigate potential safety risks.

Strict Adherence to Safety Standards

We adhere to stringent safety standards in all our operations. These standards are not just industry requirements but a reflection of our commitment to excellence in safety. Our adherence includes:

- Compliance with Regulations: We ensure full compliance with all local, national, and international safety regulations.

- Use of Personal Protective Equipment (PPE): Our team is equipped with the necessary PPE, such as helmets, gloves, and safety glasses, to protect them from potential hazards.

- Safe Work Environment: We maintain clean and organised work environments to minimise the risk of accidents and ensure the safety of everyone on-site.

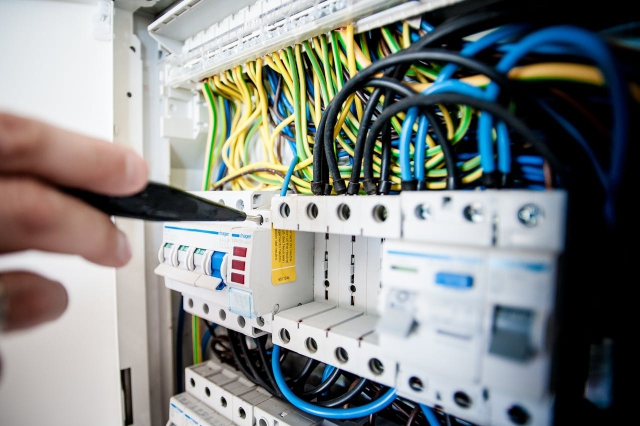

Advanced Safety Technologies

Incorporating the latest safety technologies is another way we enhance safety in our operations. These technologies help us monitor, manage, and mitigate risks effectively. Key technologies include:

- Real-Time Monitoring Systems: Advanced monitoring systems that provide real-time data on machinery performance, helping us detect and address issues promptly.

- Automated Safety Features: Machinery equipped with automated safety features that can shut down operations in case of a malfunction, preventing accidents.

- Safety Software: Utilising safety management software to track safety incidents, perform risk assessments, and ensure compliance with safety protocols.

Continuous Improvement

Safety is an ongoing priority, and we are committed to continuous improvement in all our safety practices. We regularly review and update our safety protocols to reflect the latest advancements and insights in the field. This commitment to continuous improvement ensures that our safety measures are always at the forefront of industry standards.

Get in touch

Please get in touch today to find out how we can help you.